The site contains all peer-reviewed Journals published by Universitas Sebelas Maret.

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z All

BESTUUR

BESTUUR is a peer-reviewed journal published by Department of Administrative, Faculty of Law, Universitas Sebelas Maret Surakarta. It published twice a year (August and December). Bestuur is an open access and peer-reviewed journal that aims to offer an international academic platform for cross-border legal research in Administrative Law, particularly in developing and emerging countries.

Bestuur focuses on administrative law at global, national, regional, and local levels worldwide. The journal addresses specific issues on tax law, consumer protection law, environmental law, medical law, spatial law, labour law, agrarian law, transportation law, mining law, energy law, administrative, and legal justice. Bestuur publishes peer-reviewed while increasing the efficiency of the process.

In addition, Bestuur also covers legal research in constitutional law with specific topics such as separation of powers and procedural due process, the structure and workings of the various agencies, procedural requirements for adjudication and rulemaking, enforcement discretion, methods of enforcement, government tort liability, freedom of information, and state finance.

The journal warmly welcomes contributions from scholars with related disciplines. Novelty and recency of issues, however, are the priority in publishing.

BESTUUR's New Template 2022. Since Volume 10, Number 2 2022, Bestuur uses a new template from now on. It may be subject to modifications, therefore, please download it here each time you format a paper for submission. If the submitted manuscript does not comply with the guidelines or uses a different format, it will be rejected by the editorial team before being reviewed. The editorial team will only accept a manuscript that meets the specified formatting requirements.

All manuscripts must be submitted by BESTUUR OJS system. We DO NOT accept any submissions via email at all.

View Journal | Current Issue | Register

Caraka Tani: Journal of Sustainable Agriculture

Caraka Tani: Journal of Sustainable Agriculture publishes original articles, review articles, case studies and short communications in collaboration with the Association of Indonesian Agricultural Journals (Asosiasi Jurnal Pertanian Indonesia - AJPI). This journal has two issues in a year and it will be published in April and October.

Caraka Tani: Journal of Sustainable Agriculture is an international scientific journal focused on sustainable agriculture. Referring to its name Caraka Tani (Caraka : messenger; Tani : farmer, farming, agriculture), Caraka Tani has a mission to convey the messages to the world, especially in the developing countries, for carrying out agriculture practices in a sustainable manner by paying attention to 3 main aspects of sustainability; namely: environmental health, economic profitability, and social and economic equity. These aspects are expected to be applied with regard to resources, uniqueness and specific wisdom of every region. Other aspects are also welcome as long as it can be applied in developing countries. This journal covers research in the following areas: agricultural conservation, agricultural ecology, organic farming, agro biodiversity permaculture covering the economic aspects of sustainable agriculture (agribusiness, social-economic agricultural issues, agricultural development, agroindustry), agricultural diversification, soil and water conservation, soil quality and health, agricultural climate, food science, safety and security, animal welfare, and integrated pest and disease control biologically.

To implement the quality assurance of the journal, the editorial board members were invited from various countries, such as Indonesia, Ghana, Ethiopia, Saudi Arabia, Nigeria, Malaysia, India and Iran. Meanwhile, the authors so far are from many countries such as Indonesia, Ethiopia, Philippines, Belgium, Nigeria, Tanzania, South Africa, Pakistan, South Korea, Tunisia, Ghana, Malaysia, Japan, Bangladesh, Nepal, United Kingdom, India, Australia, Iraq, Taiwan, Thailand, China, Algérie, Morocco, United States, Vietnam and Canada. Peer reviewers who have worked in the editorial process come from 43 countries; Indonesia, Rwanda, Nigeria, Tunisia, Ghana, Uganda, Ethiopia, South Africa, Egypt, Saudi Arabia, Turkey, Islamic Republic of Iran, Romania, Serbia, Italy, Poland, Spain, Belgium, Hungary, Russian Federation, Czech Republic, Pakistan, India, Bangladesh, Sri Lanka, China, Japan, Malaysia, Philippines, Thailand, Vietnam, Laos, Australia, United States, Mexico, Brazil, Colombia, Morocco, Cameroon, Malawi, Peru, United Kingdom and Iraq.

Caraka Tani: Journal of Sustainable Agriculture has been accredited for five years as scientific journal based on Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia SK No 204/E/KPT/2022 dated 3rd October 2022 (Vol. 36 No. 2 October 2021 until Vol. 41 No. 1 April 2026, see certificate) and indexed in SINTA 1.

Caraka Tani: Journal of Sustainable Agriculture has been also accepted and listed in Scopus, Web of Science™, Directory of Open Access Journals (DOAJ), Centre for Agriculture and Bioscience International (CABI) and ranked in SCImago Journal & Country Rank [SJR].

Update April 19, 2024 05:00 AM GMT+7 | Published printed issues P-ISSN on web in 2017 since Vol. 16, No. 1, March 2001 | Activated open journal system since January 2018 | Published online issues E-ISSN since Vol. 33, No. 1, April 2018

View Journal | Current Issue | Register

Yustisia

| Journal title | Yustisia |

| Initials | Yustisia |

| Frequency | Three times per year (April, August, and December) |

| DOI | Prefix 10.20961 |

| Online ISSN | 2549-0907 |

| Print ISSN | 0852-0941 |

| Editor-in-chief | Dr. Anang Setiyawan,S.H.,M.H. |

| Publisher | Faculty of Law, Universitas Sebelas Maret, Surakarta Indonesia |

Yustisia is open access, double-blind peer-reviewed law journal published by the Faculty of Law, Universitas Sebelas Maret three times a year in April, August, and December. The specialty of this journal is that it publishes articles in contemporary legal studies with an interdisciplinary approach, Environmental Policy, Human Rights, and Democracy issues. The Journal publishes articles (Research and Review Article) and Book Review.

Yustisia is Nationally Accredited journal (Accreditation Rank SINTA 1) by the Minister of Research and Technology/National Research and Innovation Agency of the Republic of Indonesia Decision No. 169/E/KPT/2024.

View Journal | Current Issue | Register

SAINS TANAH - Journal of Soil Science and Agroclimatology

SAINS TANAH - Journal of Soil Science and Agroclimatology (journal initial: STJSSA; p-ISSN 1412-3606 e-ISSN 2356-1424) is open access, academic, citation indexed, and peer-reviewed journal published by the Department of Soil Science, Faculty of Agriculture, Universitas Sebelas Maret. It covers original research articles, review, and short communication on diverse topics related to soil science and agricultural climatology (read more ...). We accepting submission from all over the world. All submitted articles shall never be published elsewhere, original and not under consideration for other publication.

STJSSA has been accredited by National Journal Accreditation (ARJUNA) Managed by Ministry of Research and Technology/ National Agency for Research and Innovation, the Republic of Indonesia with First Grade (Sinta 1) according to the Decree No. 204/E/KPT/2022 (link).

STJSSA has been indexed, abstracted, displayed in SCOPUS, DOAJ, ASEAN Citation Index (ACI), SINTA by Ristek/BRIN of The Republic of Indonesia, GOOGLE Scholar, etc.

View Journal | Current Issue | Register

INDONESIAN JOURNAL OF APPLIED PHYSICS

Indonesian Journal of Applied Physics, a journal provides rapid publication and important research in fields of physics, This journal covers research in the following areas: Materials physics, Theoretical & Computational physics, Instrumentation, and Geophysics Tracks ( read more...). We accept submission from all over the world. All submitted articles shall never be published elsewhere, original and not under consideration for other publication.

To implement the quality assurance of the journal, the editorial board members were invited from various countries, such as Indonesia, France, Mexico, Malaysia, Japan, India, China, Australia, and Finland. Meanwhile, the authors are from many countries such as Indonesia, Japan, the United States, Finland, the United Kingdom, Australia, Malaysia, Pakistan, Turkey, Mesir, India, China, Timor Leste, Taiwan, and Nigeria). Peer reviewers who have worked in the editorial process come from many countries, such as Indonesia, Egypt, Bangladesh, Mexico, Turkey, Malaysia, India, and the United Kingdom.

IJAP has been accredited by National Journal Accreditation (ARJUNA) Managed by Ministry of Research, Technology, and Higher Education, Republic Indonesia with First Grade ( SINTA 1 ) since year 2023 to 2026 according to the decree No. 0041/E5.3/HM.01.00/2023.

Article Processing Cost is FREE for manuscript submitted by overseas author/s. Manuscript written by Indonesian author/s collaborated with overseas author/s will be charged 50% DISCOUNT of the APC.

View Journal | Current Issue | Register

ALCHEMY Jurnal Penelitian Kimia

ALCHEMY Jurnal Penelitian Kimia is a peer-reviewed, open-access journal publishes original research articles or review articles both theoretical and experimental studies on all aspects of fundamental and applied chemistry, including organic, inorganic, analytical, physical, computational chemistry, sustainable, green, and environmental. ALCHEMY Jurnal Penelitian Kimia covers studies in emerging fields of current innovative chemistry. Moreover, ALCHEMY Jurnal Penelitian Kimia pays special attention to the studies related to the exploration research of minerals and natural materials, including plant extracts that grow in Southeast Asia. ALCHEMY Jurnal Penelitian Kimia published twice a year in March and September.

View Journal | Current Issue | Register

JKPK (Jurnal Kimia dan Pendidikan Kimia)

ISSN: 2503-4146 (print); ISSN: 2503-4154 (online).

The JKPK (Jurnal Kimia dan Pendidikan Kimia) is a rank 2 accredited scientific journal based on the Decree of the Director-General of Research and Development Strengthening of the Ministry of Research, Technology and Higher Education of the Republic of Indonesia No. 28/E/KPT/2019.

This national journal is devoted to the publication of original research on chemistry (fundamental, process, and applied chemistry) and chemistry education. Published three times annually (April, August, and December) where the submitted articles in English. Manuscripts must be original and never been published elsewhere, must be submitted online or through email: jkpk@fkip.uns.ac.id. Please learn the “Author Guidelines” before beginning your manuscript submission.

View Journal | Current Issue | Register

Journal of Maobi

Journal of Maobi is a scientific periodical published by the Confucius Institute, at Universitas Sebelas Maret which focuses on the development of Chinese studies. The scope of the publication is in the latest studies and research in the fields of language, linguistic, teaching, education, literature, culture, philology, history, and journalism. Journal articles are the result of studies and research originating from literature studies, field research, and best practice of literation of the Chinese studies. Each article contains the latest information by prioritizing the values of novelty, originality and usefulness. The purpose of publishing is to actively improve the quality and accessibility of scientific knowledge in the fields of language, linguistic, teaching, education, literature, culture, philology, history, and journalism. Journal of Maobi is published twice a year, in May and November. Every article published by Journal of Maobi has gone through a strict review and editorial process and respects the provisions of copyright law, privacy and scientific publication ethics. The informational content of this journal is open access under a Creative Commons Attribution 4.0 International License (CC BY-4.0).

View Journal | Current Issue | Register

Livestock and Animal Research

p-ISSN 2721-5326 | e-ISSN 2721-7086

Livestock and Animal Research (Livest. Anim. Res.) publishes original research article in the field of livestock and other animal research. This journal previously titled as Sains Peternakan: Jurnal Penelitian Ilmu Peternakan and changed into Livestock and Animal Research in order to broaden the distribution and increase the visibility of the journal. This journal is published three times a year: March, July, and November by Sebelas Maret University associated with Perkumpulan Insinyur dan Sarjana Peternakan Indonesia (ISPI). The first edition with new journal-title is published in July 2020 (Vol. 18 No. 2) while previous editions remain the same as the previous journal that can be accessed through website: https://jurnal.uns.ac.id/Sains-Peternakan.

Livestock and Animal Research has been accredited and categorized as Sinta 2 by Directorate General of Strengthening Research and Development – Ministry of Research, Technology and Higher Education, Republic of Indonesia in 2019 (No. 10/E/KPT/2019).

Currently, Livestock and Animal Research has been accredited and categorized as Sinta 3 started from Volume 21 No. 1 2023 up to Volume 25 No. 3 2027 by Directorate General of Higher Education, Research, and Technology – Ministry of Education, Culture, Research, and Technology, Republic of Indonesia in 2023 (No. 152/E/KPT/2023).

In addition, this journal has been indexed by Crossref, Google Scholar, Mendeley, Garuda (Garda Rujukan Digital), i-Focus, i-Journals, and Udledge.s

The interest of Livestock and Animal Research covering: 1) Animal Production System; 2) Animal Breeding and Genetics; 3) Animal Physiology and Reproduction; 4) Animal Nutrition and Feeding Technology; 5) Technology of Animal Product; 6) Animal Biotechnology; 7) Animal Behaviour and Welfare; 9) Socio-Economics in the field of Animal Research, and 10) Animal health. The objects of the research can be livestock, laboratory, exotic, and/or wild animals. This journal uses double blind review where all the review processes using anonymous system so that both reviewer and author identities are not revealed during the process.

View Journal | Current Issue | Register

JPSCR: Journal of Pharmaceutical Science and Clinical Research

JPSCR: Journal of Pharmaceutical Science and Clinical Research (e-ISSN 2503-331X), published by Universitas Sebelas Maret in collaboration with Indonesian Pharmacist Association (Ikatan Apoteker Indonesia; IAI), is an open-access and peer-reviewed journal. JPSCR offers a forum for publishing original research articles from contributors and for novel technology news related to pharmaceutical science and clinical research.

Scientific articles on natural products, pharmaceutical sciences and industry, and clinical research are particularly welcome. JPSCR encompasses research articles, original research reports, reviews, short communications, and scientific commentaries in pharmaceutical science and clinical research, including formulation and pharmaceutical product evaluation, pharmacology, biopharmaceutics & drug delivery, pharmacokinetics, nanotechnology, pharmaceutical chemistry, and analysis, as well as natural products or active pharmaceutical ingredients. JPSCR also accepts papers in clinical research, e.g., pharmacoepidemiology, clinical pharmacy, pharmacoeconomy, and pharmacovigilance. Since July 2020, JPSCR has not received any articles related to pharmaceutical management, pharmaceutical social behavior & and administration. Since 2021, JPSCR has been published three times per year, every April, August, and December.

View Journal | Current Issue | Register

Jurnal Teknologi Hasil Pertanian

Jurnal “Teknologi Hasil Pertanian” (ISSN: 1979-0309 (Print) 2614-7920 (Online)), publishes original articles and review articles on the fundamentals, applications, and management of Agricultural Product Technology areas. The journal's aim is to offer scientist, researchers and other related professionals the opportunity to share their finding and disseminate knowledge in all the related topics of biotechnology, quality management, and technologies associated with production or product development.

Jurnal “Teknologi Hasil Pertanian” published by Department of Food Science and Technology, Faculty of Agriculture, Universitas Sebelas Maret in collaboration with Asia Pacific Network for Sustainable Agriculture, Food and Energy (SAFE-Network).

View Journal | Current Issue | Register

International Journal of Pedagogy and Teacher Education

| Journal title | International Journal of Pedagogy and Teacher Education |

| Initials | IJPTE |

| Frequency | Two issues per year (April and October) |

| DOI | Prefix 10.20961 |

| Online ISSN | 2549-8525 |

| Print ISSN | 2597-7792 |

| Editor-in-chief | Gunarhadi |

| Publisher | Faculty of Teacher Training and Education, Universitas Sebelas Maret, Surakarta Indonesia |

IJPTE publishes original research and review articles, including field research pertinent to the method and practice of teaching, especially as an academic subject or theoretical concept within the context of pre-service or in-service teacher development.

Papers that address the connections between reflection, knowledge, and practice, critical analyses of particular programs, development initiatives, technology, assessment, and policy matters, as these topics relate to the main focuses of the journal, are welcome.

View Journal | Current Issue | Register

Sinolingua: Journal of Chinese Studies

Sinolingua: Journal of Chinese Studies is a scientific periodical published by the Department of Chinese Language and Culture, at Universitas Sebelas Maret which focuses on the development of Chinese studies. This journal is an English and Chinese language journal to publish written works and research results on the Chinese Studies of language, literature, culture, philology and history. Journal articles are the result of studies and research originating from literature studies, field research, and best practice of literation of the Chinese language and culture. Each article contains the latest information by prioritizing the values of novelty, originality and usefulness. The purpose of publishing is to actively improve the quality and accessibility of scientific knowledge in the fields of Chinese studies. The article will be reviewed by internal and external editors, with at least two reviewers who have related expertise with double-blind peer review. Along with the development of technological systems in the field of literacy, on March 22 2023, the Sinolingua Journal used the Online Journal System (OJS) with E-ISSN numbers: 2986-1969 and P-ISSN: 2986-9773. Sinolingua journal is published twice a year, in March and September. Every article published by Sinolingua Journal has gone through a strict review and editorial process and respects the provisions of copyright law, privacy and scientific publication ethics. The informational content of this journal is open access under a Creative Commons Attribution 4.0 International License (CC BY 4.0).

View Journal | Current Issue | Register

ENVIRO: Journal of Tropical Environmental Research

View Journal | Current Issue | Register

Journal of Cooperative, Small and Medium Enterprise Development

ISSN 2963-6264 (Online)

Journal of Coorporative Small and Medium Enterprise Development (COSMED) merupakan jurnal media publikasi hasil penelitian, pengabdian dan pemikiran bidang Koperasi dan UMKM dalam arti luas. Jurnal ini diterbitkan oleh Pusat Studi Pendampingan Koperasi dan Usaha Mikro Kecil Menengah (PSP-KUMKM), Lembaga Penelitian dan Pengabdian (LPPM), Universitas Sebelas Maret dan berkolaborasi dengan Asosiasi Bussiness Development Services Indonesia (DPN ABDSI). Jurnal ini terbit dua kali dalam satu tahun, yaitu bulan Mei dan November.

View Journal | Current Issue | Register

Journal of Midwifery in Community (JMC)

| Journal title | Journal of Midwifery in Community |

| Initials | JMC |

| Frequency | twice a year |

| DOI | Prefix 10.20961 |

| Online ISSN | 2988-6384 |

| Editor-in-chief | Luluk Fajria Maulida, S.ST., M.Keb |

| | |

| Publisher | Program Studi Sarjana dan Pendidikan Profesi Bidan Fakultas Kedokteran Universitas Sebelas Maret |

Journal of Midwifery in Community (JMC) is a platform focused on improving community well-being through applied research that addresses potentials, obstacles, challenges, and issues found in communities. These research efforts involve community and partner participation, and the resulting applied research manuscripts are published in the journal.

View Journal | Current Issue | Register

Jurnal Ilmiah Psikologi Candrajiwa

Jurnal Ilmiah Psikologi Candrajiwa (JIP Candrajiwa) is a scientific publication media published by the Faculty of Psychology Sebelas Maret University, Surakarta.

JIP Candrajiwa accept articles in various fields of psychology, especially with topic related to indigenous psychology, counseling and psychotherapy, development psychology, social psychology, and industry psychology.

JIP Candrajiwa published since 2012 through https://candrajiwa.psikologi.fk.uns.ac.id/. Starting from 2021, JIP Candrajiwa published articles through https://jurnal.uns.ac.id/candrajiwa in twice a year (June and December).

View Journal | Current Issue | Register

Agricultural Socio-Economic Empowerment and Agribusiness Journal

Agricultural Socio-economic Empowerment and Agribusiness Journal (AGRISEMA) is a jurnal for the publication of research results, reviews of previous research results, and/or ideas in the fields of agricultural socio-economics, agribusiness management, agribusiness development, agricultural policy, empowerment of agribusiness community, and sustainability of agribusiness.

Agricultural Socio-economic Empowerment and Agribusiness Journal is published by Faculty of Agriculture Universitas Sebelas Maret every June and December. The journal also has been accredited for five years as scientific journal based on Ministry of Higher Education, Science and Technology of the Republic of Indonesia SK No 10/C/C3/DT.05.00/2025 dated March 21st, 2025, as scientific journal (Vol. 1 No. 1 June 2022 until Vol. 5 No. 2 December 2026, see certificate) and indexed in DOAJ and SINTA 4. AGRISEMA Journal also collaborates with Asosiasi Jurnal Pertanian Indonesia (AJPI) dan Perhimpunan Ekonomi Pertanian Indonesia (PERHEPI).

View Journal | Current Issue | Register

Proceedings National Conference PKM Center

Proceedings National Conference PKM Center merupakan diseminasi hasil pelaksanaan penelitian di bidang pengabdian masyarakat, eksakta, sosial humaniora, inovasi dan kewirausahaan. Tidak hanya itu tetapi juga hasil dari pengabdian masyarakat dan utamanya adalah hasil Program Kreativitas Mahasiswa dari mahasiswa Universitas Sebelas Maret juga dimuat di dalamnya. Proceedings ini dikelola oleh PKM Center UNS dan pertama kali diagendakan di bulan Desember tahun 2020. ISSN 2797-3387 Link ISSN: https://issn.lipi.go.id/terbit/detail/20210603410859758

FULL PROCEEDINGS:https://bit.ly/FULLPROCEEDINGSPKMUNS

View Journal | Current Issue | Register

Jurnal Pengembangan Pendidikan Akuntansi dan Keuangan (JPPAK)

| Journal title | Jurnal Pengembangan Pendidikan Akuntansi dan Keuangan |

| Initials | JPPAK |

| Frequency | 2 (two) times a year |

| DOI | Prefix 10.20961 |

| Online ISSN | 2807-6575 |

| Print ISSN | -- |

| Editor-in-chief | Prof. Dr. Siswandari M.Stat |

| Managing Editor | Asri Diah Susanti |

| Publisher | Accounting Education Study Program, Faculty of Teacher Training and Education, Sebelas Maret University |

View Journal | Current Issue | Register

Journal of Biodiversity and Biotechnology

Journal of Biodiversity and Biotechnology is a scientific journal focused on biodiversity and biotechnology published twice a year (June and December) managed and published by Universitas Sebelas Maret. This journal covers original research in the following areas: biodiversity and environment, biotechnology, agriculture biotechnology, food biotechnology, medical biotechnology, bioinformatics, molecular biology, biochemistry, bioinformatics, phyto-pharmacy, herbal medicine, and animal science. Other topics are welcome if it discusses about biodiversity or biotechnology.

View Journal | Current Issue | Register

Journal of Disability

| Journal title | Journal of Disability |

| Initials | JoD |

| Frequency | Twice a year (June and December) |

| DOI | Prefix 10.20961 |

| Online ISSN | 2828-4542 |

| | |

| Editor-in-chief | Prof. Munawir Yusuf |

| Managing Editor | Dr. Joko Yuwono |

| Publisher | Pusat Studi Difabilitas LPPM of Universitas Sebelas Maret |

The Journal of Disability is an open-access and peer-reviewed journal dedicated to publishing new research in the field of disability. Details about our focus and scope can be found here. The Journal of Disability is published twice a year June and December. Recipients of current research articles that have the potential to make a significant contribution to the exploration and development of science related to disability issues. Articles submitted to this journal should feature well-thought out study designs, appropriate data analysis, and interpretation. Journal of Disability published by Pusat Studi Difabilitas LPPM at Universitas Sebelas Maret collaboration ASOSIASI PROFESIONAL ORTOPEDAGOGIK INDONESIA (APOI).

View Journal | Current Issue | Register

Solo Journal of Anesthesi, Pain and Critical Care (SOJA)

Solo Journal of Anesthesi, Pain and Critical Care (SOJA) is a scientific journal by Department of Anesthesiology and Intensive Therapy, Faculty of Medicine Sebelas Maret University. SOJA Focuses Case Report, Original Research and Review Article in the scope of : Life Support, Emergency and Trauma, Cardiovascular Anesthesia, Pediatric Anesthesia, Neuro Anesthesia, Pain Management, Intensive Care, Obstetry Anesthesia, Geriatric and Oncology Anesthesia, Regional Anesthesia, Ambulatory Anesthesia. SOJA is an English language journal. This journal is published every 6 months with 5 articles (April and October) by Solo Journal of Anesthesi, Pain and Critical Care (SOJA).

View Journal | Current Issue | Register

Translation and Linguistics (Transling)

| Journal Title | Translation and Linguistics |

| Initials | TL |

| Frequency | 3 Issues Per Year (March, July, November) |

| DOI | 10.20961/transling |

| Print ISSN | 2807-2766 |

| Online ISSN | 2807-3924 |

| Editor-in-chief | Dr. Arifuddin, Lc., M.A. |

| Publisher | Postgraduate Program of Linguistics, Faculty of Cultural Sciences, Universitas Sebelas Maret |

Translation and Linguistics (Transling) is an open-access, academic, and peer-reviewed journal published by Postgraduate Program of Linguistics, Faculty of Cultural Sciences, Universitas Sebelas Maret (UNS). The journal publishes original research articles, literature studies, and scientific papers in a wide range of linguistic fields, including phonetics, phonology (read more …). It accepts submissions from all over the world. All submitted articles shall never be published elsewhere, original and not under consideration for other publication.

View Journal | Current Issue | Register

Smart Society Empowerment Journal

Smart Society Empowerment Journal (SSEJ) is published by Faculty of Medicine Universitas Sebelas Maret. SSEJ is a peer-reviewed and open-access journal focusing on educative, promotive, preventive and community empowerment activities in the health sector

Ready for submitting a manuscript? Please follow [Author Guidelines] and click [Register] or [Login].

Journal Contact

Faculty of Medicine, Universitas Sebelas Maret

Jl. Ir. Sutami 36A Kentingan, Jebres, Surakarta, Jawa Tengah

Email: ssefkuns@mail.uns.ac.id

View Journal | Current Issue | Register

Journal of Morality and Legal Culture

Journal of Morality and Legal Culture is a peer-reviewed journal published by the Doctoral of Legal Science Program, Faculty of Law, University of Sebelas Maret. It published twice times a year (July and December). This Journal aims primarily to facilitate scholarly and professional discussions over current developments on legal issues in Indonesia as well as to publish innovative legal researches concerning Indonesian laws and legal systems. It provides immediate open access to its content on the principle that making research freely available to the public supports a greater global exchange of knowledge. Published exclusively in English, the Review seeks to expand the boundaries of Indonesian legal discourses to access English-speaking contributors and readers all over the world. Novelty and recency of issues, however, are a priority in publishing.

The scope of the articles published in this journal deals with a broad range of topics in the fields of Civil Law, Criminal Law, International Law, Administrative Law, Islamic Law, Constitutional Law, Environmental Law, Procedural Law, Anthropological Law, Health Law, Law and Economics, Sociology of Law and another section related contemporary issues in Law (Social science and Political science).

Journal of Morality and Legal Culture is an open-access journal which means that all content is freely available without charge to the user or his/her institution (for libraries or individuals). Users (for libraries or individuals) are allowed to read, download, copy, distribute, print, search, or link to the full texts of the articles, or use them for any other lawful purpose, without asking prior permission from the publisher or the author.

View Journal | Current Issue | Register

Res Publica: Jurnal Hukum Kebijakan Publik

Res Publica is a peer-reviewed journal published by Constitutional Law Department, Faculty of Law, Universitas Sebelas Maret three times a year in April, August, and December. This Journal aims primarily to facilitate scholarly and professional discussions over current developments on legal issues in Indonesia as well as to publish innovative legal researches concerning constitutional law and democracy. It provides immediate open access to its content on the principle that making research freely available to public support a greater global exchange of knowledge. Published exclusively in English and / or Bahasa Indonesia (will be considered), the Review seeks to expand the boundaries of Indonesian legal discourses to access English-speaking contributors and readers all over the world. Novelty and recency of issues, however, is a priority in publishing. The scope of the articles published in this journal deal with a broad range of topics in the fields of constitutional law and democracy. Res Publica is an open access journal which means that all content is freely available without charge to the user or his/her institution (for libraries or individual). Users (for libraries or individual) are allowed to read, download, copy, distribute, print, search, or link to the full texts of the articles, or use them for any other lawful purpose, without asking prior permission from the publisher or the author.

View Journal | Current Issue | Register

AgriHealth: Journal of Agri-food, Nutrition and Public Health

P-ISSN 2272-0656 | E-ISSN 2272-0648

AgriHealth: Journal of Agri-food, Nutrition and Public Health, published by Research and Development Center for Food, Nutrition and Public Health (P4GKM) LPPM Universitas Sebelas Maret, is a journal that contains scientific articles on the results of studies on the application of science and technology to stakeholders in the fields of environmentally friendly agriculture, food, nutrition and public health. AgriHealth in collaboration with Association of Indonesian Agricultural Journals (AJPI) and published 2 (two) times every year in April and October.

AgriHealth: Journal of Agri-food, Nutrition and Public Health has been accredited for five years as scientific journal based on Ministry of Higher Education, Science and Technology of the Republic of Indonesia SK No 10/C/C3/DT.05.00/2025 dated March 21st, 2025 (Vol. 5 No. 1 April 2024 until Vol. 9 No. 2 October 2028, see certificate) and indexed in SINTA 2. This journal also has been accepted for inclusion in the Centre for Agriculture and Bioscience International (CABI) and Directory of Open Access Journals (DOAJ).

To implement the quality assurance of the journal, the editorial board members were invited from various countries, such as Indonesia, Nigeria, Malaysia, India, and Australia. Meanwhile, the authors so far are from many countries such as Indonesia, Viet Nam, Taiwan, Nigeria, Democratic People's Republic of Korea, United Kingdom, South Africa, Pakistan, Thailand, Japan, Uganda, Malaysia, and Brunei Darussalam. Peer reviewers who have worked in the editorial process come from 6 countries; Indonesia, Malaysia, Pakistan, Thailand, Philippines, and Kenya.

View Journal | Current Issue | Register

Journal of Global Environmental Dynamics

Journal of Global Environmental Dynamics - an international journal published by Study Program of Environmental Science, Faculty of Mathematic and Natural Science, Sebelas Maret University. The research article submitted to this online journal will be peer-reviewed. The accepted research articles will be available online (free download) following the journal peer-reviewing process. The language used in this journal is English.

Focus and Scope

The Journal of Global Environmental Dynamics, an international journal, provides a forum for publishing the novel research and technologies. This journal includes Original Research Articles, Review Articles, and Short Communications relating to:

- Environmental Management

- Environmental Ecology

- Environmental Engineering

- Environmental pollution

- Conservation of Natural Resources and the Environment

- Development and Environment

- Environmental Impact Analysis

- Environmental Planning and Administration

- Renewable energy

- Energy Conversion Technology

- Energy Management and Policy

- Green Technology

- Health, Safety and Environment

- Environmental Information System

Publication Schedule: April, July, November

View Journal | Current Issue | Register

Biological Journal of Indonesia

View Journal | Current Issue | Register

Jurnal Ilmiah Media, Public Relations, dan Komunikasi (IMPRESI)

Jurnal Ilmiah Media, Public Relations, dan Komunikasi (IMPRESI) ISSN 2722-4562 (Online) and 2721-9674 (Print) is a peer-reviewed journal published by Department of Communication Science, Faculty of Social and Political Sciences, Universitas Sebelas Maret. It is published twice a year (April and October). Journal IMPRESI aims primarily to provides direct access to the content of the research results freely available to support knowledge exchange globally. The area of Jurnal IMPRESI is a research result and theoretical thinking about communication studies. Published exclusively in English and/or Bahasa Indonesia. In each edition, it received an original article that will be reviewed by internal and external editors.

View Journal | Current Issue | Register

Smart Sport

SMART SPORT diterbitkan oleh Universitas Sebelas Maret Surakarta, dikelola oleh Program Studi Pendidikan dan Kepelatihan Olahraga, Fakultas Keolahragaan dengan Nomor EISSN:2723-3081. Terbit dua kali dalam setahun pada bulan Februari dan Oktober, berisi naskah hasil penelitian, gagasan konseptual, kajian dan aplikasi teori maupun Ilmu Pengetahuan dan Teknologi Olahraga.

SMART SPORT adalah jurnal ilmiah yang berisikan hasil penelitian, gagasan konseptual, kajian, dan aplikasi teori maupun ilmu pengetahuan dan teknologi olahraga. Jurnal ini berisi artikel ilmiah tentang filsafat olahraga, sejarah olahraga, pedagogi olahraga, psikologi olahraga, sosiologi olahraga, biomekanika olahraga, kedokteran olahraga, motor learning, motor development, training and coaching, manajemen olahraga, infrastruktur olahraga, industri olahraga, komunikasi dan media massa olahraga, ekonomi olahraga, hukum olahraga, dan politik olahraga.

View Journal | Current Issue | Register

PHEDHERAL

PHEDERAL: Physical Education, Health, and Recreation Journal (ISSN: 1979-3103) is open to seeking innovation, creativity, and novelty. PHEDHERAL Journal is a peer-review journal published by the Universitas Sebelas Maret Surakarta. The aim of the journal is to facilitate scientific publication of the results of researches in Indonesia and participate to boost the quality and quantity of research for academics and researchers. This journal accepts manuscripts in Bahasa or English.

PHEDHERAL Journal published twice a year, in May and November by publishing research results and critical analysis studies in the field of Physical Education, Sports Tourism, Sports Coaching, Physical Activity, Sports Biomechanics, Sports Pedagogy, Sports Physiology, Sports Psychology, and Traditional Sports.

View Journal | Current Issue | Register

Prosiding Seminar Nasional Linguistik dan Sastra (SEMANTIKS)

Prosiding Seminar Nasional Linguistik dan Sastra (SEMANTIKS) merupakan media publikasi berupa prosiding dari hasil Seminar Nasional Linguistik dan Sastra (SEMANTIKS).

Semantik (Seminar Sastra dan Linguistik) merupakan nama kegiatan ilmiah yang sudah dilakukan sejak awal S2 Linguistik Pascasarjana UNS berdiri. Nama tersebut sengaja dipertahankan untuk memperlihatkan bahwa kegiatan ini merupakan kelanjutan dari kegiatan yang pernah ada. Kegiatan tersebut sudah beberapa kali dilakukan, lalu berhenti. Mulai tahun 2019, kegiatan tersebut akan dihidupkan lagi untuk menggairahkan kehidupan keilmuan linguistik, dan sastra. Mulai tahun 2019 nama seminar berubah menjadi Seminar Nasional Linguistik dan Sastra (SEMANTIKS). Dalam perkembangannya, bidang terjemahan digabungkan dalam Program S2 Linguistik. Karena itu, cakupan Semantiks 2019 meliputi bidang terjemahan juga. Semantiks akan dilaksanakan setiap tahun. Pada tahun 2022 Prosiding SEMANTIKS yang terindeks ISBN pada tahun 2019 berganti terindeks ISSN (Online dan Print).

View Journal | Current Issue | Register

Matriks Teknik Sipil

| Journal Title | Jurnal Matriks Teknik Sipil |

| Initials | MATEKSI |

| Editor-in-Chief | Lydia Novitriana Nur Hidayati, ST., MSc., PhD |

| Frequency | Two issues per year (June and December) |

| DOI Prefix | 10.20961 |

| P-ISSN | 2354-8630 |

| E-ISSN | 2723-4223 |

| Publisher | Universitas Sebelas Maret |

| Address | Jl. Ir. Sutami No. 36A, Surakarta, Indonesia |

Matriks Teknik Sipil (MATEKSI) merupakan jurnal ilmiah yang diterbitkan oleh Program Studi Teknik Sipil Universitas Sebelas Maret (UNS) sebagai wadah publikasi bagi mahasiswa, dosen, peneliti, dan praktisi di bidang teknik sipil baik dari dalam maupun luar UNS. Jurnal ini terbit dua kali dalam setahun, yaitu pada bulan Juni dan Desember, dengan tujuan menyebarluaskan hasil penelitian serta inovasi terkini dalam bidang teknik sipil. Ruang lingkup jurnal mencakup berbagai topik meliputi geoteknik, struktur dan bahan bangunan, hidroteknik, transportasi, serta manajemen konstruksi, sehingga diharapkan dapat menjadi sarana pengembangan ilmu pengetahuan dan teknologi yang relevan dengan kebutuhan pembangunan berkelanjutan.

Announcements

Matriks Teknik Sipil (MATEKSI) sejak tahun 2024 mengalami perubahan frekuensi penerbitan dari yang semula empat kali setahun menjadi dua kali setahun, yaitu pada bulan Juni dan Desember.

View Journal | Current Issue | Register

Sabdasastra : Jurnal Pendidikan Bahasa Jawa

p-ISSN 2620-343X | e-ISSN 2986-3074

Sabdasastra : Jurnal Pendidikan Bahasa Jawa (Sabdasastra : Journal of Javanese Language Education) is an open-access journal published by Department of Javanese Language Education, Faculty of Teacher Training and Education, Universitas Sebelas Maret. The first issue of 2017 Volume 1 No 1 has ten articles. Sabdasastra has two issues in a year and it will be published in March and September. The focus and scope of this journal are language education, literature, philology, linguistics, culture, and local wisdom in Java. Sabdasastra has been indexed in Google scholar, Dimensions, and GARUDA. The Editors receive scientific writing from researchers, lecturers, and students on education, teaching, language, and literature in Java.

View Journal | Current Issue | Register

GEADIDAKTIKA

The GEADIDAKTIKA Journal is a multidisciplinary journal covering all fields of education and science related to geography, demography and the environment. The purpose of writing this journal are to reveal facts, problems and problem solving that can be used as input for Government, institutions, society and individual. Geadidaktika Journal is peer-reviewed journal published by Sebelas Maret University.

GEADIDAKTIKA Journal published twice a year, namely in January and August.

GEADIDAKTIKA journal welcomes scientific research papers, review papers and discussion papers dealing with environmental sustainability issues from such fields as the biological sciences, agriculture, geology, meteorology, energy, food sciences, soil and water sciences, geography, education.

View Journal | Current Issue | Register

Kalam Cendekia: Jurnal Ilmiah Kependidikan

Kalam Cendekia: Jurnal Ilmiah Kependidikan is a peer-reviewed interdisciplinary journal with broad coverage, consolidating basic and applied research activities. Kalam Cendekia aims to become one of the centers for scientific publications of articles that focus on education and teaching, which include: learning innovation, curriculum development, educational technology, educational evaluation, and teacher education.

View Journal | Current Issue | Register

PRIMA: Journal of Community Empowering and Services

PRIMA: Journal of Community Empowering and Services (Online ISSN: 2579-5074) is an open-access academic journal published by the Faculty of Agriculture, Universitas Sebelas Maret Surakarta. PRIMA stands for Pemberdayaan dan Rekayasa Iptek Masyarakat Agraris in Indonesian. This journal has two issues in a year and it will be published in June and December. This journal accepts manuscript in Bahasa or English.

PRIMA: Journal of Community Empowering and Services is a scientific journal as a media for publishing the results of scientific thoughts and studies on the application of science and technology to stakeholders in the agricultural sector (more ...)

View Journal | Current Issue | Register

Equilibrium Journal of Chemical Engineering

Equilibrium Journal of Chemical Engineering (EJChE) is an open-access journal published by Universitas Sebelas Maret. EJChE publishes communication articles, original research articles, and review articles. This Journal has been previously named Ekuilibrium published since 2002 with P-ISSN: 1412-9124 (2007) (https://jurnal.uns.ac.id/ekuilibrium). In 2017, the name of EJChE with e-ISSN 2622-3430 (2018) was introduced as a continuation of Ekuilibrium without any policy changes. This journal has been accredited by the Ministry of Education, Culture, Research and Technology No. 164/E/KPT/2021, 27 December 2021 (indexed in 4). There are 2 (two) issues of publication each year.

Starting in 2023, the official language of EJChE is English (see journal template). The manuscript submission and reviewing process is fully conducted through an online journal system using a double-blind review process.

EJChE accepts announcements regarding conferences, special issues, and other related scientific advertisements which are related to the Focus and Scope of the EJChE. The special issue or any form of review for a manuscript subjected to publication in EJChE, must strictly follow the guidelines provided for authors, reviewers, and editors.

EJChE invites scholars, researchers, and practitioners to publish their articles and also provides forums for them to share their works, experiences, and knowledge of current topics related to chemical engineering, including:

Biochemical Process Exploration and Optimization

Bioprocess Technology

Chemical Education

Chemical Reaction Kinetics and Catalysis

Chemurgy Technology

Designing, Modeling, and Process Optimization

Energy and Conversion Technology

Food Technology

Material Development

Membrane Technology

Natural Dyes Technology

Process System Engineering and products

Separation and Purification Technology

Thermodynamics

Waste Treatment Technology

View Journal | Current Issue | Register

Nuansa Indonesia: Jurnal Ilmu Bahasa, Sastra, dan Filologi

View Journal | Current Issue | Register

Journal of Law, Society, and Islamic Civilization

Journal of Law, Society, and Islamic Civilization (JoLSIC) is managed by Law and Society Department, Faculty of Law, Universitas Sebelas Maret, and published twice a year, in April and October.

It provides immediate open access to its content on the principle that is making research freely available to the public to support a greater global exchange of knowledge. Journal of Law, Society, and Islamic Civilization (JoLSIC) focuses on Islamic Law and Customary Law at global, national, regional, and local levels worldwide. The journal addresses specific issues on Islamic Family Law, Islamic Economic Law, Islamic Criminal Law, Adat Law, Legal Pluralism, and other law and society issues.

View Journal | Current Issue | Register

DEDIKASI: Community Service Reports

| Journal title | DEDIKASI: Community Service Reports |

| Initials | DEDIKASI |

| Frequency | Twice a year on January and July |

| DOI | Prefix 10.20961 |

| Online ISSN | 2715-5706 |

| Print ISSN | -- |

| Editor-in-chief | Prof. Nurdin |

| Publisher | Faculty of Teacher Training and Education, Universitas Sebelas Maret, Surakarta |

DEDIKASI: Community Service Reports publishes reports on the research dissemination and community services. It is our interest to elaborate the method applied during the research dissemination and the implications of the implementation to the process, understanding, and community social economic development. It is expected that the journal could become a publication outlet for meaningful information about community services activities especially to the readers who want to conduct, improve, or create novel community service activities. This journal is published by the Faculty of Teacher Training and Education, Universitas Sebelas Maret, Surakarta Indonesia.The journal will be published twice in a year in January and July. Manuscript submission is all year round.

View Journal | Current Issue | Register

Mekanika: Majalah Ilmiah Mekanika

View Journal | Current Issue | Register

Agrista

Agrista: Jurnal Ilmiah Mahasiswa Agribisnis UNS

Agrista adalah Jurnal Ilmiah Mahasiswa Agribisnis Program Studi Agribisnis Fakultas Pertanian UNS Surakarta yang merupakan wahana publikasi skripsi mahasiswa Program Studi Agribisnis. Agrista terbit 4 kali setahun ( Maret, Juni, September, Desember ).

Tema-tema yang diangkat di meliputi sosial ekonomi pertanian, usaha tani, studi kelayakan pertanian manajemen agribisnis, manajemen strategi agribisnis, pengembangan mutu agribisnis, pembangunan pertanian, kebijakan pertanian, pemasaran , ketahanan pangan, dan perencanaan pembangunan wilayah.

View Journal | Current Issue | Register

Nozel : Jurnal Pendididikan Teknik Mesin

NOZEL : Jurnal Pendidikan Teknik Mesin is a national forum for the publication and dissemination of original work which contributes to greater scientific understanding of the main disciplines underpinning the mechanical engineering and vocational education.

This journal is dedicated to the latest advancements in mechanical engineering and vocational education. The goal of this journal is to provide a platform for scientists and academicians all over the world to promote, share, and discuss various new issues and developments in different areas of mechanical engineering and vocational education.

This journal is published in the online and print journal, which publishes research articles, reviews, and letters in all areas of mechanical engineering and vocational education. It is a blind peer-reviewed journal, aims to provide the most complete and reliable source of information on current developments in the field. The emphasis will be on publishing quality papers rapidly and available to researchers worldwide.

View Journal | Current Issue | Register

Jurnal Bahasa, Sastra, dan Studi Amerika

Jurnal Bahasa, Sastra, dan Studi Amerika (JBSSA), Journal of Language, Literature and American Studies is an open access and a peer reviewed journal organized by English Department of UNS, published by Universitas Sebelas Maret, Surakarta Indonesia. The aim of the journal is to provide a forum for language, literature, translation, American Studies, and Cultural Studies researchers and practitioners to share their research results and theories in the areas of English and Indonesian languages, linguistics, foreign languages and literature and culture, and translation. Articles are published in Indonesian and English.

View Journal | Current Issue | Register

Journal of ASEAN Dynamics and Beyond

Journal of ASEAN Dynamics and Beyond is an international, interdisciplinary and open access social sciences journal covering a variety of topics (culture, economics, geography, politics, society) from both historical and contemporary perspectives. The topics should be related to the ASEAN or Southeast Asia, but are not restricted to the geographical region, when spatial and political borders of Southeast Asia are crossed or transcended, e.g., in the case of linguistics, diaspora groups or forms of socio-cultural transfer. The Journal publishes two issues per year and we welcome submissions at any time. The journal invites both established as well as young scholars to present research results and theoretical or methodical discussions, to report about on-going research projects or field studies, to publish conference reports, to conduct interviews with experts in the field, and to review relevant books. Articles should be submitted in English.

View Journal | Current Issue | Register

Javanologi: International Journal of Javanese Studies

Javanologi: International Journal of Javanese Studies (e-ISSN: 3025-1877) is a semiannual journal, published in June and December, first publication is in 2017 by Indonesian Institute of Sciences, Ministry of Research, Technology, and Higher Education of the Republic of Indonesia No. 0005.25806122/JI.3.1/ SK.ISSN/2017.07, 5 July 2017. This journal contents are managed by Institute Javanology and Graduate of Javanese Language Education, Universitas Sebelas Maret, is a medium for scholarly discussion, description, and surveys concerning literature, linguistics, archaeology, history, philosophy, library and information studies, religion, art, and interdisciplinary of Javanese studies.

View Journal | Current Issue | Register

Verstek

Jurnal Verstek (E-ISSN:2355-0406 & P-ISSN:2355-0406) is a peer-reviewed journal published by Procedural Law Department, Faculty of Law, Universitas Sebelas Maret three times a year in March, June, September and December. This Journal aims primarily to facilitate undergraduate students paper over current developments on procedural law issues in Indonesia as well as to publish innovative legal researches concerning Indonesian procedural laws and legal system.

This journal publishes scholarly articles covering a broad range of topics in Procedural Law, including legal doctrines and constructions, critical analyses of procedural law in practice, contemporary developments and trends, as well as practical and technical challenges in the application and enforcement of procedural law.

View Journal | Current Issue | Register

BELLI AC PACIS (Jurnal Hukum Internasional)

Belli Ac Pacis (Jurnal Hukum Internasional) with eISSN: 2721-0596 is a open access, double peer review law journal published by the International Law Department Faculty of Law Universitas Sebelas Maret. Modern international law in the last few decades has experienced very rapid development, this is characterized by the emerge of the State in a modern sense, as well as a legal system that regulates relations between countries and international legal entities with each other. Relations between countries are no longer limited by absolute sovereignty, for example in the case of war crimes, the international community could sue countries or even individuals to be responsible for these actions based on universal principles. Belli ac Pacis (Jurnal Hukum Internasional) Journal presents the multifarious developments in contemporary international law as a study of current State practices. The Belli ac Pacis (Jurnal Hukum Internasional) Journal encompasses Public International Law, International Law of the Sea, International Humanitarian Law, International Environmental Law, International Criminal Law, International Organizational Law, International Dispute Settlement Law, Diplomatic Law, Air and Space Law, International Trade Organization Law, ASEAN Law, and International Economic Law.

View Journal | Current Issue | Register

Ekosains

Jurnal Ekosains mempublikasikan hasil penelitian di bidang lingkungan maupun interdisipliner terkait yang belum pernah dipublikasikan atau tidak sedang dipertimbangkan untuk dipublikasikan di jurnal lain.

Jurnal Ekosains menerima artikel baik dalam Bahasa Indonesia maupun Bahasa Inggris yang mencakup beberapa topik kajian lingkungan antara lain:

- Manajemen lingkungan

- Ekologi Lingkungan

- Konservasi Sumber Daya Alam dan Lingkungan

- Pembangunan dan Lingkungan

- Analisis Mengenai Dampak Lingkungan

- Perencanaan dan Administrasi Lingkungan

- Kesehatan lingkungan

- Teknik Lingkungan dan Pencemaran Lingkungan, dan

- Sistem Informasi Lingkungan

- Manajemen Bencana

View Journal | Current Issue | Register

TEXFILE Jurnal Ilmiah Tekstil

TEXFILE Journal of Textile memfokuskan pada tulisan ilmiah yang berkaitan dengan tekstil pada wilayah kriya, desain, seni, maupun budaya. Artikel berupa hasil penelitian, proyek inovasi, aplikasi teori, atau gagasan konseptual.

View Journal | Current Issue | Register

Indonesian Journal of Applied Statistics

Indonesian Journal of Applied Statistics (IJAS) (e-ISSN: 2621-086X) is a journal published by Study Program of Statistics, Universitas Sebelas Maret, Surakarta, Indonesia in collaboration with Forum Pendidikan Tinggi Statistika (FORSTAT). This journal is published twice every year, in May and November. The editors receive scientific papers on the results of research, scientific studies, and problem solving research using statistical method. Received papers will be reviewed to assess the substance of the material feasibility and technical writing.

Indonesian Journal of Applied Statistics (IJAS) is included in: Dimensions, SINTA, Google Scholar, Crossref, Garuda, and Mendeley database.

View Journal | Current Issue | Register

Social, Humanities, and Educational Studies (SHES): Conference Series

Social, Humanities, and Educational Studies (SHEs): Conference Series is a peer-reviewed interdisciplinary journal with broad coverage, consolidating basic and applied research activities by publishing the manuscript of the conference in all areas of the social sciences, humanities and education.

View Journal | Current Issue | Register

Teknodika

Teknodika (p-ISSN: 1693-9107 & e-ISSN: 2656-6621) is peer reviewed journal of educational technology research which publishes reviews, analysis, dan empirical research on designing, developing, managing, utilizing and evaluating educational Technology to facilitating learning and improving performance in both formal and informal educational settings.

Teknodika is is a nationally accredited scientific journal with the predicate of Sinta in 3rd rank which published by Master Program of Educational Technology Faculty of Teacher Training and Education, Universitas Sebelas Maret, Indonesia in collaboration with Asosiasi Program Studi Teknologi Pendidikan Indonesia (APS-TPI) & SEAMEO Regional Open Learning Centre (SEAMOLEC) which publishes Twice a year on March and September. We call for international authors to contribute for priority, quick, and highly disseminated publication. Our journal is a member of crossreff by doi : 10.20961/teknodika, and has been indexed and abstracted in various indexing databases: Science and Technology Index (Sinta) | Google scholar | Garuda | Dimension | Index Copernicus | Crossref | ROAD | Moraref | Directory of Research Journals Indexing (DRJI) | Indonesia One Search (IOS)

Focus & scope includes: Learning Media, Learning Resources, E-learning, Distance Learning, Online Learning, Learning Evaluation, Instructional Design, Learning Models, Learning with TPACK Approach (Technological Pedagogical Content Knowledge), and other relevant topics in the field of Educational Technology.

View Journal | Current Issue | Register

Basastra: Jurnal Bahasa, Sastra, dan Pengajarannya

Basastra: Jurnal Bahasa, Sastra, dan Pengajarannya is published twice a year in April and October (ISSN 2302-6405) contains scientific articles on language, literature, and its relation to teaching, about linguistics and applied linguistics studies, about the literary studies, and about the literary teaching and learning. It has been published by the Department of Indonesian Language Education, Faculty of Language and Literature, Universitas Sebelas Maret Surakarta in cooperate with Asosiasi Dosen Bahasa dan Sastra Indonesia (ADOBSI). The articles are written in both Indonesian and foreign languages. Articles that include the analysis, study, and application of theory, research results, and discussion of the literature.

The manuscript submitted has not been published anywhere both printed or electronic. The author shall refer to the author guidelines before submitting the manuscript. The manuscript submitted will then be evaluated and edited in terms of format, terms used, and other applied styles.

Since volume 7 number 1 in 2019, Basastra: Jurnal Bahasa, Sastra, dan Pengajarannya migrate to the jurnal.uns.ac.id/basastra page, while the 2012 edition up to 2017 is published on the jurnal.fkip.uns.ac.id. The published articles can be accessed and downloaded for free through the Sebelas Maret University Electronic Journal PortaI.

AD

1. Article decision accepted or REJECTED no later than 2 months after the author submits the article

2. Submission file must be in .docx/.doc (Ms. Word).

3. Phone number/HP MUST be listed on the account profile

View Journal | Current Issue | Register

Jurnal Pendidikan Matematika dan Matematika SOLUSI

| Online ISSN | 2614-0357 |

| Publisher | Mathematics Education Dept., Faculty of Teacher Training and Education, Universitas Sebelas Maret |

| Editor in Chief | Dr. Dra. Yuli Bangun Nursanti, M.Pd. |

| Description | JPMM SOLUSI is an open access journal containing research results and ideas in the field of mathematics education and pure and applied mathematics (analysis, algebra, applied mathematics and statistics) |

| Focus & Scope | The subject matter of the journal includes the following and related issues: 1. Mathematics Education (STEM, Ethnomathematics, School Mathematics Education, Higher Education Mathematics Education) 2. Mathematics (Analysis, Algebra, Statistics, Applied Mathematics, Geometry and Computation) |

View Journal | Current Issue | Register

Jurnal Pendidikan Kimia

Jurnal Pendidikan Kimia ISSN 2337-9995 merupakan jurnal resmi yang dikelola dan diterbitkan secara online oleh Program Studi Pendidikan Kimia, Fakultas Keguruan dan Ilmu Pendidikan, Universitas Sebelas Maret Surakarta. Jurnal ini terbit 2 kali dalam setahun, berisi artikel-artikel ilmiah dari hasil penelitian dan pembelajaran kimia.

View Journal | Current Issue | Register

PKn Progresif : Jurnal Pemikiran dan Penelitian Kewarganegaraan

PKn Progresif: Pemikiran dan Penelitian Kewarganegaraan E-ISSN: 2621-1904 P-ISSN: 1907-5332 is open acces journal, published by Faculty of Teacher Traning and Education, Sebelas Maret University on Juny and December. This journal focuses on: Civics, Citizenship Studies, Citizenship Science, Value and Norms Education, Legal Education, Political Education, Classroom Action Research (Civic Education), Development of teaching and learning Citizenship Education (models, methods, media, sources, evaluations), Study of learning content on Civic Education, Study of Civic Education curriculum in school, Study of Civic Education curriculum in elementary, middle and higher education. The journal welcomes original research articles, review papers, case studies, and theoretical discussions that contribute to the advancement of knowledge in these fields.

View Journal | Current Issue | Register

Early Childhood Education and Development Journal

| Journal title | Early Childhood Education and Development Journal |

| Initials | ECEDJ |

| Frequency | Three issues per year (April, August, and December) |

| DOI | Prefix 10.20961 |

| Online ISSN | 2716-0637 |

| Print ISSN | 2684-7442 |

| Editor-in-chief | Upik Elok Endang Rasmani |

| Publisher | Department of Teacher Training of Early Childhood Education, Faculty of Teacher Training and Education, Universitas Sebelas Maret, Surakarta Indonesia |

View Journal | Current Issue | Register

Jurnal Tania

Jurnal Tania dipublikasikan oleh Program Studi Pendidikan Ekonomi, Fakultas Keguruan dan Ilmu Pendidikan, Universitas Sebelas Maret. Jurnal Tania terbit 2 kali dalam satu tahun. Jurnal Tania dikhususkan untuk artikel mahasiswa Prodi Pendidikan Ekonomi. Topik artikel yang bisa disubmit pada jurnal ini meliputi: Pendidikan Ekonomi, Ilmu Pendidikan, Ilmu Ekonomi, Manajemen, Pemasaran, dan Keuangan.

View Journal | Current Issue | Register

Journal of Informatics and Vocational Education

View Journal | Current Issue | Register

Recidive : Jurnal Hukum Pidana dan Penanggulangan Kejahatan

Recidive : Jurnal Hukum Pidana dan Penanggulangan Kejahatan (e-ISSN:2775-2038) is a peer-reviewed journal published by the Criminal Law Department, Faculty of Law, Universitas Sebelas Maret three times a year in April, August, and December. This Journal aims primarily to facilitate undergraduate students paper over current developments on criminal law issues in Indonesia as well as to publish innovative legal construction of the money laudering law, corruption law,criminology, and financial crimes. It provides immediate open access to its content on the principle that making research freely available to public support a greater global exchange of knowledge.

View Journal | Current Issue | Register

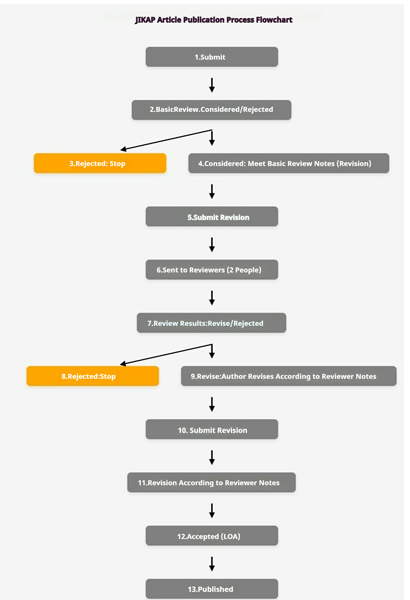

JIKAP (Jurnal Informasi dan Komunikasi Administrasi Perkantoran)

JIKAP (Jurnal Informasi dan Komunikasi Administrasi Perkantoran/Journal of Information and Communication in Office Administration) is published by the Office Administration Education Study Program, Faculty of Teacher Training and Education, Sebelas Maret University with Online ISSN: 2614-0349. It is published six times yearly in January, March, May, July, September, and November. This journal aims to facilitate scientific and professional discussions regarding the latest developments in Information and Communication issues in the field of Office Administration as well as innovative studies in the field of education. JIKAP accepts English and Indonesian manuscripts.

View Journal | Current Issue | Register

Journal of Development and Social Change

1.png) | Journal of Development and Social Change adalah sebuah jurnal yang diterbitkan secara periodik setiap bulan April dan Oktober oleh Program Studi Sosiologi, Fakultas Ilmu Sosial dan Politik, Universitas Sebelas Maret (UNS) Surakarta. Jurnal ini lahir berdasarkan surat keputusan Kepala Pusat Nasional ISSN Bapak Hendro Subagyo, M.Eng., dengan keputusan No. : 0005.26145766/JI.3.1/SK.ISSN/2018.01 pada tanggal 26 Januari 2018 untuk ISSN Media Cetak. Kemudian berdasarkan surat Keputusan Kepala Pusat Nasional ISSN Bapak Hendro Subagyo, M.Eng., No. : 0005.26157187/JI.3.1/SK.ISSN/2018.03 untuk ISSN Media Online. Jurnal ini terbit pertama kali pada bulan April 2018 yang dimulai dengan Edisi Vol. 1, No. 1, April 2018. Jurnal ini memfokuskan pada hasil penelitian, review teori dan metodologi dan juga review buku dalam perspektif keilmuan sosiologi terutama terkait pokok persoalan pembangunan dan perubahan sosial dalam persepektif nasional maupun internasional. |

View Journal | Current Issue | Register

Jurnal Pustaka Ilmiah

About Journal

Jurnal Pustaka Ilmiah (JPI) is a peer-reviewed journal published by UNS Library. JPI is a medium for librarians, teachers, lecturers, and practitioners in continuing professional development. Creative ideas become research material implemented in various models of library development dissemination, both print and online. Creativity is the root of the development of lifelong learning with multiple models of literacy culture development in the library. The beauty and accuracy of scientific writing can be realized to produce leading human resources by reading and writing to illuminate the world. Literacy culture is an effort to develop and empower libraries as centers of learning resources to support the Three Pillars of Higher Education (Tri Dharma Perguruan Tinggi).

JPI will be published every June and December each year.

View Journal | Current Issue | Register

Smart Medical Journal

Smart Medical Journal (SmedJour) is published by Faculty of Medicine Universitas Sebelas Maret. SMedJour publishes original research articles or systematic review in the basic medical sciences, clinic medical sciences, medical education and public health.

Ready for submitting a manuscript? Please follow [Author Guidelines] and click [Register] or [Login].

Journal Contact

Fak. Kedokteran Universitas Sebelas Maret

Jl. Ir. Sutami 36A Kentingan, Jebres, Surakarta, Jawa Tengah

Email: smjfkuns@gmail.com/smjfkuns@mail.uns.ac.id

View Journal | Current Issue | Register

Placentum: Jurnal Ilmiah Kesehatan dan Aplikasinya

Placentum: Jurnal Ilmiah Kesehatan dan Aplikasinya (p-ISSN: 2303-3746; e-ISSN: 2620-9969) is an open-access academic journal published by the Midwifery Department, Universitas Sebelas Maret Surakarta in collaboration with Ikatan Bidan Indonesia (IBI). This journal has three issues in a year and it will be published in February, August, and December. This journal accepts manuscript in English.

Placentum: Jurnal Ilmiah Kesehatan dan Aplikasinya publishes original research articles or review articles in Maternal and Child Health, Health Promotion, and Epidemiology. (more ...)

This journal has been accredited by National Journal Accreditation (ARJUNA) Managed by the Ministry of Research and Technology/ National Agency for Research and Innovation, the Republic of Indonesia with third grade (Sinta 3) according to the Decree No. 152/E/KPT/2023 (link).

View Journal | Current Issue | Register

Proceeding of International Conference on Art, Language, and Culture

Proceeding of International Conference on Art, Language, and Culture publishes the result of International Conference on Art, Language, and Culture

View Journal | Current Issue | Register

Jurnal Hukum dan Pembangunan Ekonomi

| |

Jurnal Hukum dan Pembangunan Ekonomi is a peer-reviewed journal published by the Master of Law-Postgraduate Program, Faculty of Law, Universitas Sebelas Maret. It published twice times a year (July and December). This Journal aims primarily to facilitate scholarly and professional discussions over current developments on legal issues in Indonesia as well as to publish innovative legal research concerning Indonesian laws and legal systems. It provides immediate open access to its content on the principle that making research freely available to the public supports a greater global exchange of knowledge. Published exclusively in English and/or Bahasa Indonesia, the Review seeks to expand the boundaries of Indonesian legal discourses to access English-speaking contributors and readers all over the world. Novelty and recency of issues, however, are a priority in publsihing. The scope of the articles published in this journal deals with a broad range of topic in the fields of Civil Law, Criminal Law, International Law, Administrative Law, Islamic Law, Constitutional Law, Environmental Law, Procedural Law, Anthropological Law, Law and Economics, Sociology of Law and another section related contemporary issues in law.

View Journal | Current Issue | Register

Jurnal Privat Law

Jurnal Privat Law (eISSN: 2715-5676) is open access, double-blind peer-reviewed law journal published by the Faculty of Law, Universitas Sebelas Maret. It was born on March 11, 2012 in order to canalise the ideas of scientific research articles for the academic community, especially in the field of Civil Law.

Its main objective is to facilitate scientific and professional discussions on current developments on legal issues in Indonesia as well as to publish innovative legal research on Indonesian law and the legal system. The focus and scope of this journal is legal issues in the fields of Civil Law and Business Law.

Jurnal Privat Law is Nationally Accredited (Accreditation Rank IV) by the Minister of Research and Technology/National Research and Innovation Agency of the Republic of Indonesia Decision No. 164/E/KPT/2021

View Journal | Current Issue | Register

Notary Law Review

Jurnal Notary Law Review adalah jurnal yang diterbitkan oleh Program Kenotariatan Fakultas Hukum Universitas Sebelas Maret tiga kali setahun pada bulan Januari, April dan Agustus. Jurnal ini bertujuan terutama untuk memfasilitasi diskusi ilmiah dan profesional mengenai perkembangan terkini mengenai permasalahan dibidang hukum di Indonesia dan juga menerbitkan penelitian hukum yang inovatif mengenai hukum dan sistem hukum Indonesia. Ini memberi akses terbuka langsung ke kontennya berdasarkan prinsip bahwa membuat penelitian tersedia secara bebas untuk mendukung integrasi pengetahuan global yang lebih besar. Diterbitkan secara eksklusif, Review tersebut berupaya memperluas batas-batas wacana hukum Indonesia untuk mengakses kontributor dan pembaca. Ruang lingkup artikel yang dimuat dalam jurnal ini membahas berbagai topik di bidang Kenotariatan, PPAT, Agraria.

View Journal | Current Issue | Register

BISE: Jurnal Pendidikan Bisnis dan Ekonomi

Jurnal Pendidikan Bisnis dan Ekonomi is published two times a year by Department of Economics Education, Faculty of Teacher Training and Education, Universitas Sebelas Maret Surakarta, Indonesia. It publishes works in various areas of economics education including education, economics, business economics, business education, management, finance, and marketing

View Journal | Current Issue | Register

Jurnal Pendidikan Insan Mandiri

Jurnal Pendidikan Insan Mandiri is published by Master of Economics Education Study Program, Teacher Training and Education Faculty, Universitas Sebelas Maret Surakarta, Indonesia. It publishes works in various areas of economics education including education, business economics, business education, management, finance, accounting, education administration, office administration, and marketing

View Journal | Current Issue | Register

Habitus: Jurnal Pendidikan, Sosiologi, & Antropologi

Habitus Journal is published by the Sociology-Anthropology Education Study Program, FKIP, Sebelas Maret University (UNS). Published twice a year ie 1st Edition: January-June and 2nd edition: July-December. The Habitus Journal focuses on theoretical studies and analysis of research results in the fields of education, social and culture.

Journal Title : Habitus: Jurnal Pendidikan, Sosiologi dan Antropologi

Frequency : 2 issues per yearDOI : https://doi.org/10.20961/habitus.v3i2.35716 Online ISSN : 2597-9264Publisher : Program Studi Pendidikan Sosiologi Antropologi FKIP, Universitas Sebelas MaretCitation Analysis : View Journal | Current Issue | Register

Agrotechnology Research Journal

Agrotechnology Res. J. (Agrotechnology Research Journal) is a peer-reviewed, open-access scientific journal published by the Department of Agrotechnology, Universitas Sebelas Maret, in collaboration with the Indonesian Agrotechnology/Agroecotechnology Society (PAGI). The journal publishes original research articles, reviews, and scientific papers in the fields of plant production, plant breeding, land and soil management, and plant protection.

View Journal | Current Issue | Register

Wacana Publik

View Journal | Current Issue | Register

Indonesian Journal Of Civil Engineering Education

| Journal title | Indonesian Journal Of Civil Engineering Education |

| Initials | IJCEE |

| Frequency | Twice a Year in July and December |

| DOI | Prefix 10.20961 |

| Online ISSN | 2598-2931 |

| Print ISSN | 2614-378X |

| Editor-in-chief | Dr. Fajar Danur Isnantyo S.T., M.Sc. |

| Publisher | Civil Engineering Education Department, Faculty of Teacher Training and Education, Sebelas Maret University |

The Indonesian Journal of Civil Engineering Education (IJCEE) is a scientific journal promoting the study of, and interest in, civil engineering education. It is a national journal published by the Civil Engineering Education Department, Faculty of Teacher Training and Education, Sebelas Maret University, Indonesia. The Indonesian Journal of Civil Engineering Education (IJCEE) was published in 2016 and has been accredited in 2018.

View Journal | Current Issue | Register

Agrosains : Jurnal Penelitian Agronomi

Agrosains: Jurnal Penelitian Agronomi is an agricultural journal published twice a year (April and October) managed and published by Department of Agrotechnology, Faculty of Agriculture, Universitas Sebelas Maret in collaboration with Indonesia Agronomy Association (PERAGI). This journal publishes articles related to agriculture such as plant physiology, crop production, physiology and seed production, soil science, plant breeding, plant protection, agro-climatology, agroecology, and plant biotechnology.

View Journal | Current Issue | Register

JPI (Jurnal Pendidikan Indonesia): Jurnal Ilmiah Pendidikan

JPI (Jurnal Pendidikan Indonesia): Jurnal Ilmiah Pendidikan merupakan salah satu jurnal PGSD FKIP UNS, yang mengkaji tentang pendidikan Indonesia secara komprehensif baik pendidikan dasar, pendidikan menengah dan pendidikan tinggi. Bahasan kajian yang akan dikaji meliputi hal-hal terkait paedagogik dan manajemen sekolah serta pembelajaran.

View Journal | Current Issue | Register

DWIJA CENDEKIA: Jurnal Riset Pedagogik

DWIJA CENDEKIA: Journal of Pedagogical Research is a journal published by Sebelas Maret University (UNS) Surakarta. The journal is published three times a year. The journal covers research and scientific ideas on education science, social science and humanities education, and mathematics and natural science education. Article submission, review process, and publication through the open journal system (OJS).

View Journal | Current Issue | Register

Jurnal Pendidikan Dasar

Jurnal Pendidikan Dasar memiliki cakupan yang membahas tentang kajian Model Pembelajaran, Media Pembelajaran, Bahan Ajar, Manajemen Sekolah, Pendidikan Tinggi di Sekolah Dasar dan hal yang bersentuhan dengan ake SD an. Artikel yang dapat dikirim ke jurnal pendidikan dasar dapat berupa hasil penelitian dan artikel gagasan ilmiah. Jurnal diterbitkan dua kali setahun yakni bulan Maret dan September.

View Journal | Current Issue | Register

Didaktika Dwija Indria

Jurnal ini membahas tentang hal-hal yang terkait dengan bidang Ke SD an. Beberapa hal yang menjadi bahan kajian dalam jurnal ini yakni metode pembelajaran, model pembelajaran, Teknologi pembelajaran, media pembelajaran, majanemen sekolah, bahan ajar sekolah dasar. Jurnal ini diterbitkan 6 kali dalam setahun yaitu pada bulan Februari, April, Juni, Agustus, Oktober, dan Desember.

View Journal | Current Issue | Register

AGRITEXTS: Journal of Agricultural Extension

AGRITEXTS: Journal of Agricultural Extension merupakan jurnal media publikasi hasil penelitian dan pemikiran bidang penyuluhan dan komunikasi pertanian/pemberdayaan masyarakat maupun pembangunan pedesaan dalam arti luas.

AGRITEXTS: Journal of Agricultural Extension merupakan peer reviewed journal dan open acces journal dengan focus dan scope bidang pengembangan masyarakat pedesaan, perhutanan sosial, kebijakan pembangunan pertanian dan pedesaan, sumber daya manusia pertanian, kelembagaan pertanian, sosiologi pedesaan, penyuluhan pembangunan, pendampingan dan pemberdayaan masyarakat, partisipasi masyarakat, pengembangan lembaga swadaya masyarakat, pendidikan luar sekolah, sosial ekonomi pertanian, komunikasi pertanian, gender dan pembangunan, Corporate Social Responsibility (CSR), dan pemberdayaan UMKM berbasis agroindustry.